Our Story

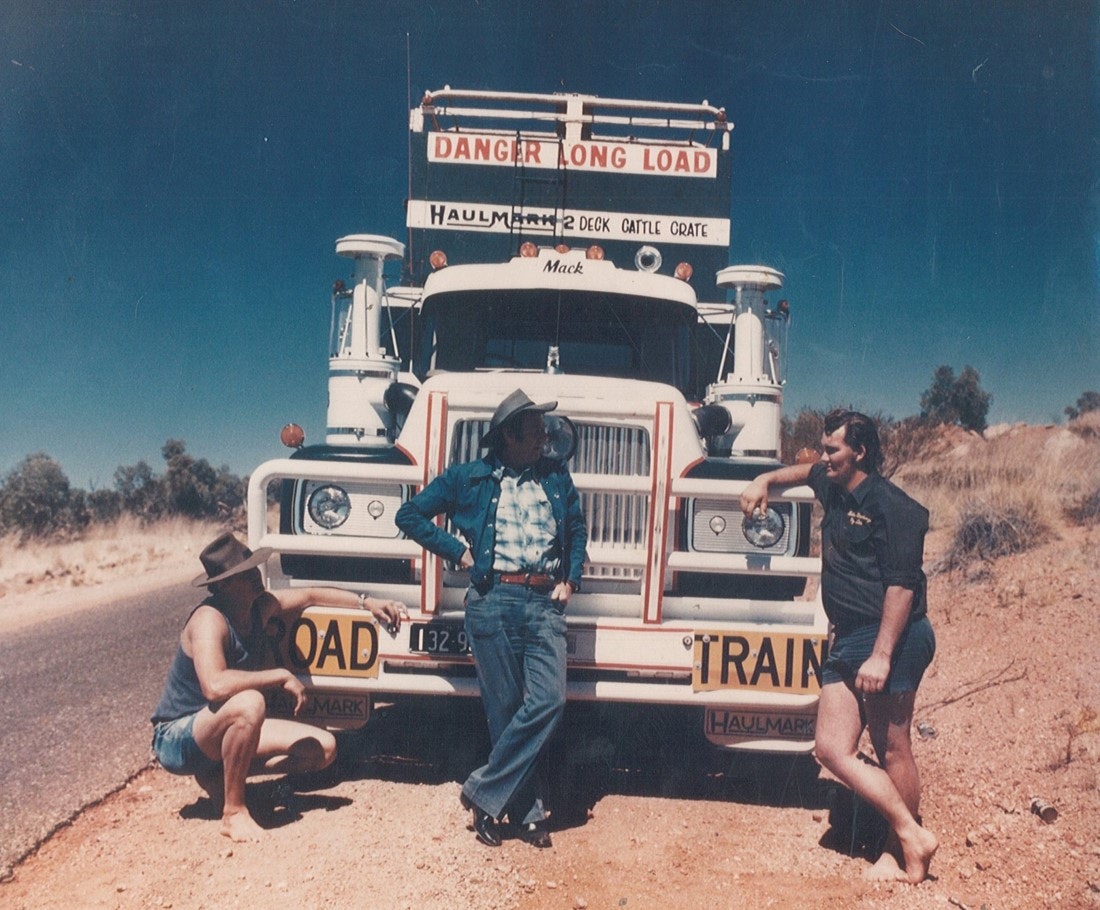

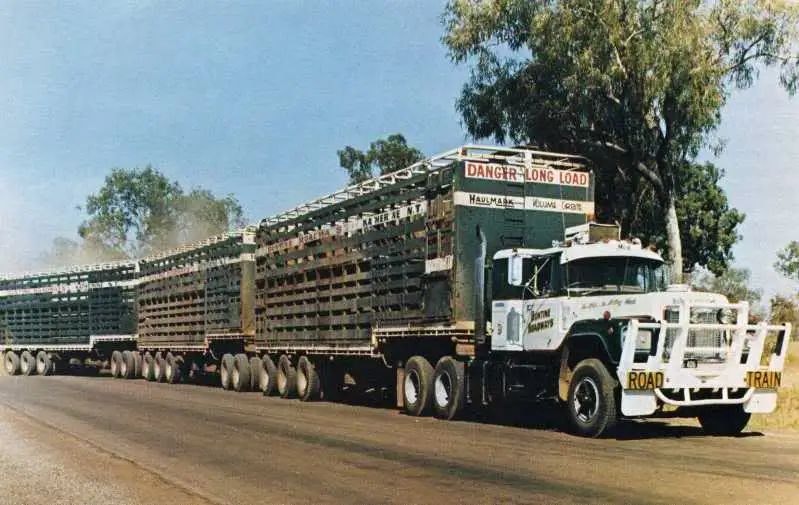

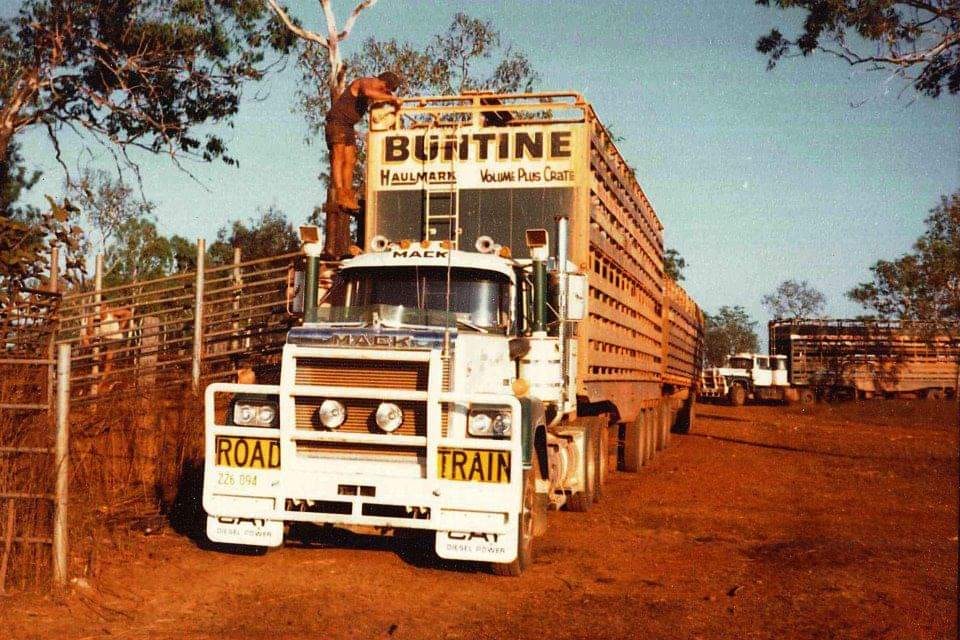

At Haulmark, we are committed to upholding the tradition of excellence that has defined our brand for over half a century.

Our vision is to continue blending time-honoured craftsmanship with innovative solutions to provide our customers with unparalleled quality and reliability in transport equipment. As we honour our legacy, we remain dedicated to advancing the industry standards and supporting the enduring success of our clients.

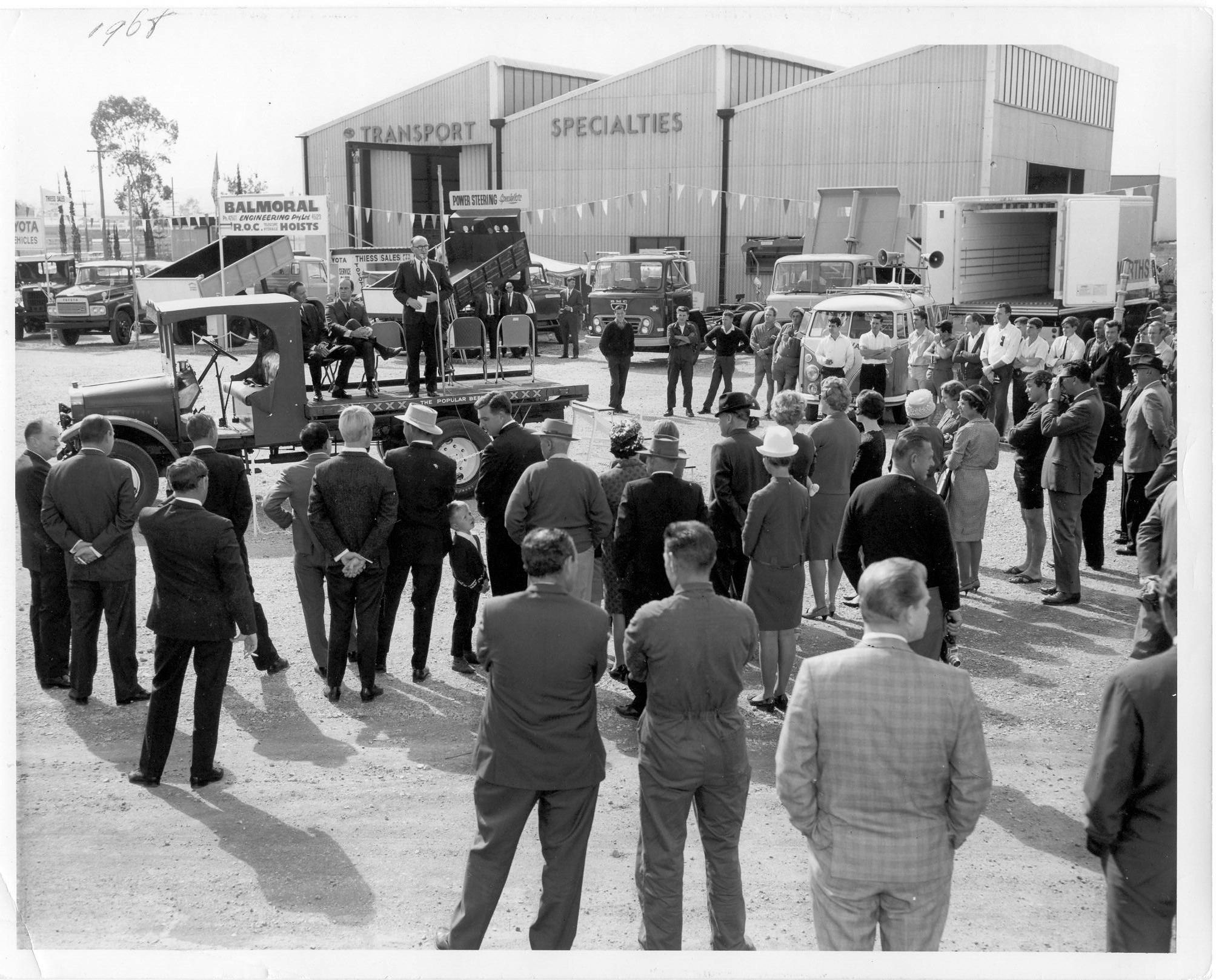

Our journey began in 1963.

Born from the vision of a few close mates in Brisbane who saw a need for robust, reliable trailers capable of enduring Australia's rugged landscapes.

Our Milestones

1963

2022

INNOVATION AND EXCELLENCE ON EVERY ROAD.

Get In Touch With Us